Our Products & Capabilities

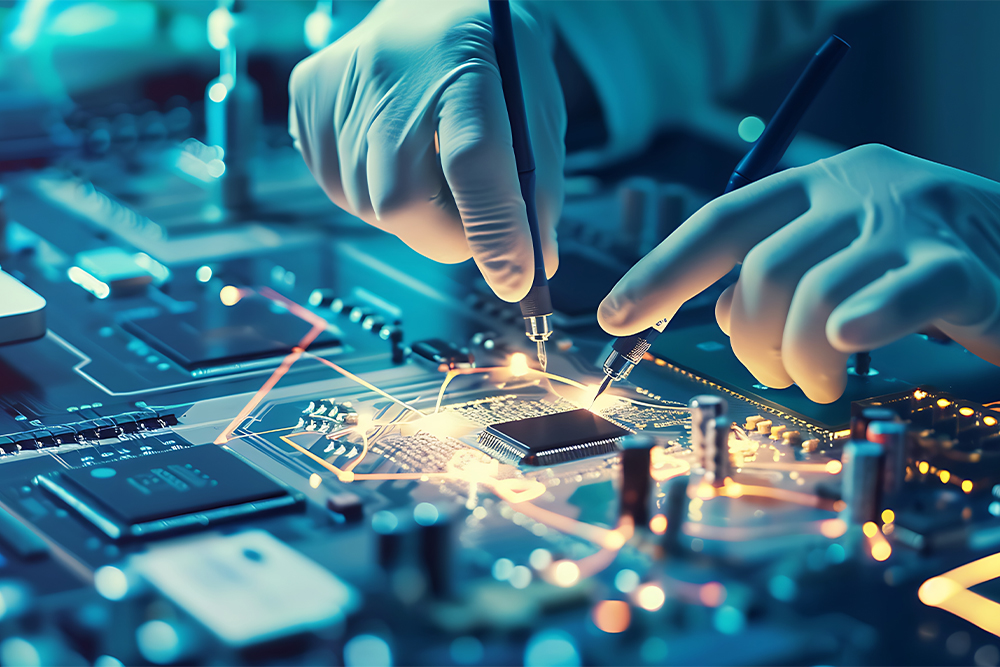

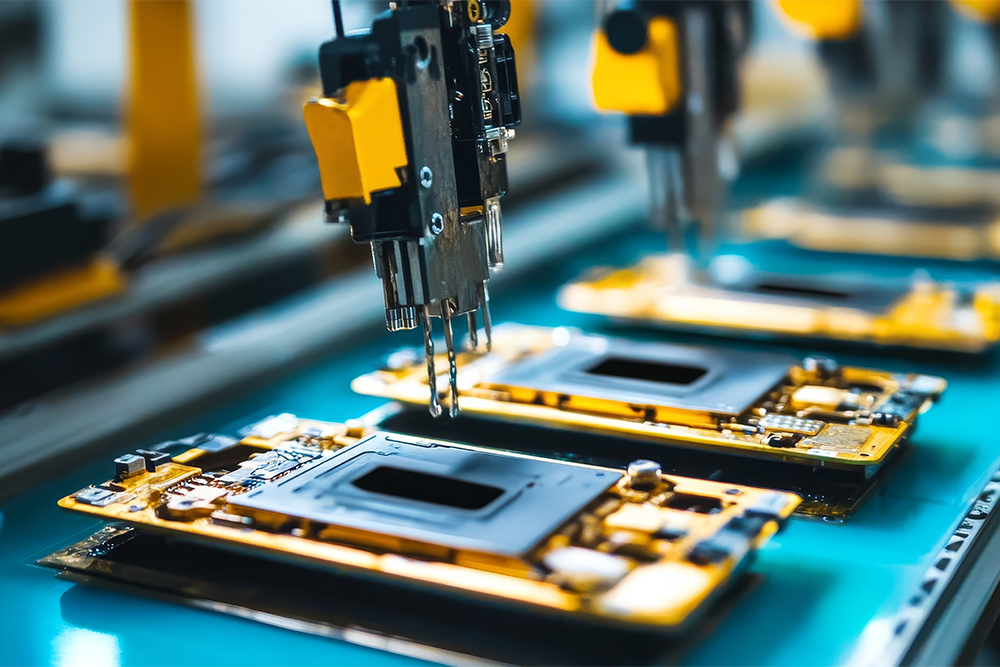

Journey Electronics designs and manufactures custom electronic assemblies including SMT and through-hole PCBs, industrial control systems, and embedded circuit solutions. We support both prototyping and full production runs for OEMs and manufacturers across the U.S.

Over the past 40 years, our circuits and control products have been trusted by industry leaders such as NCR, Corning, 3M, NASA, and Kodak—built to meet exacting specifications and backed by a commitment to consistent quality.

View Our Gallery

Certifications & Standards

Industries We Serve

Ready to Get Started?

We’d love to learn more about your project. Reach out today for a quote or to speak with our team.